Automation greatly impacts your throughput and workforce needs.

With workforce challenges and demand for your products increasing, automation is a one-stop solution to help your line.

If you haven't focused on container handling before, now's the perfect time. We provide automated machinery with flexible components to allow for product changes and growth.

Often, these are the most cumbersome, laborious areas that can benefit the most from automation by:

- Providing equipment to create pack patterns, turn containers, combine or divide them, all automatically without labor.

- Installing quick change parts that speed up changeover times while reducing the amount of people needed to perform the change over.

- Installing machines that improve throughput by automating container handling aspects.

And so much more. Visit us at PACK EXPO to learn more.

Schedule a Meeting with Us at the Show!

Resource Center

Alternate Inverting + Pick and Place Machine

Increase throughput through container handling additions such as lane combiners and dividers, turning systems, and more.

Smart Lane Combiner and Divider System

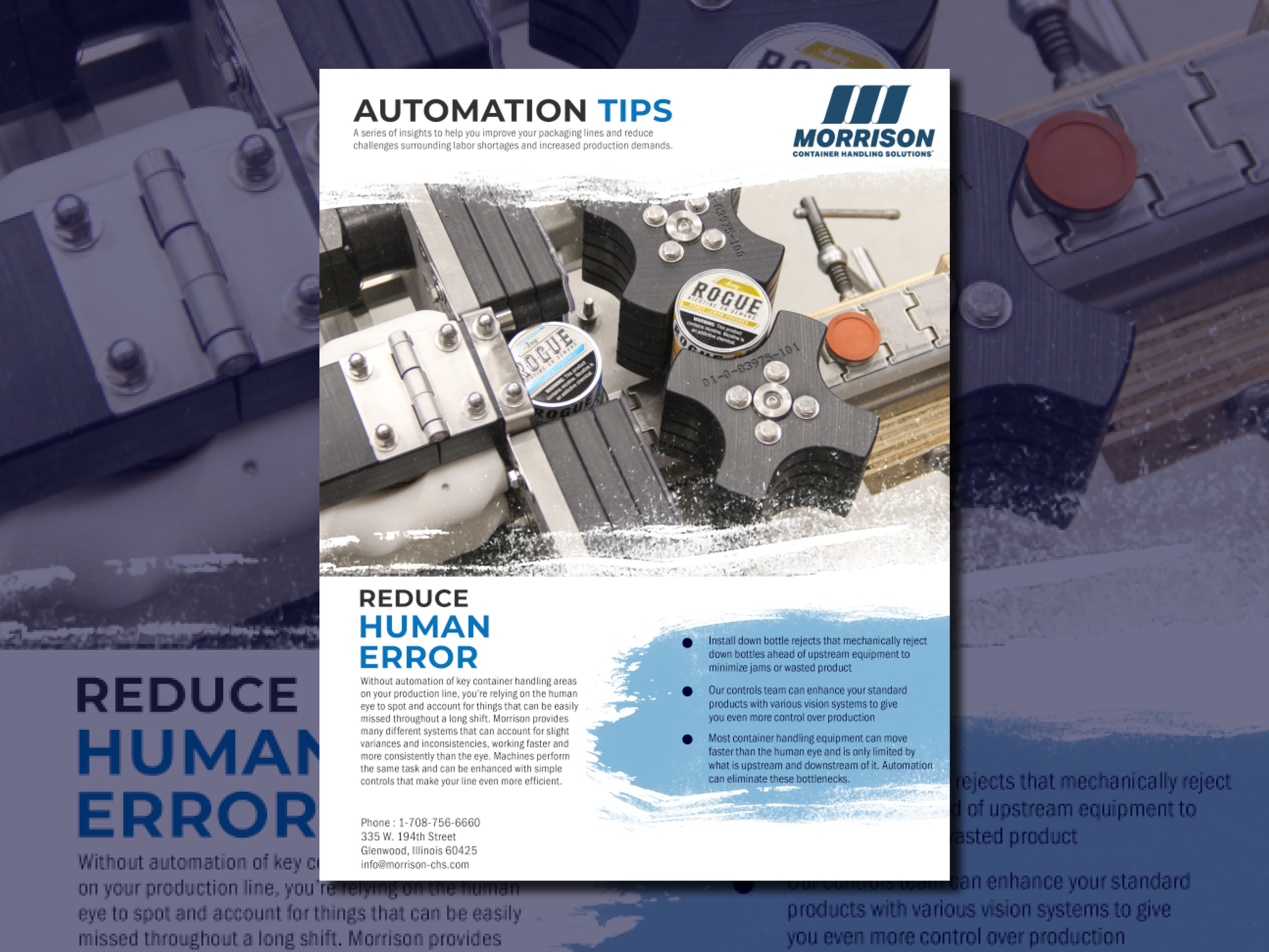

Relying on the human eye to spot things can become easily missed throughout a long shift. Automation can account for these inconsistencies.

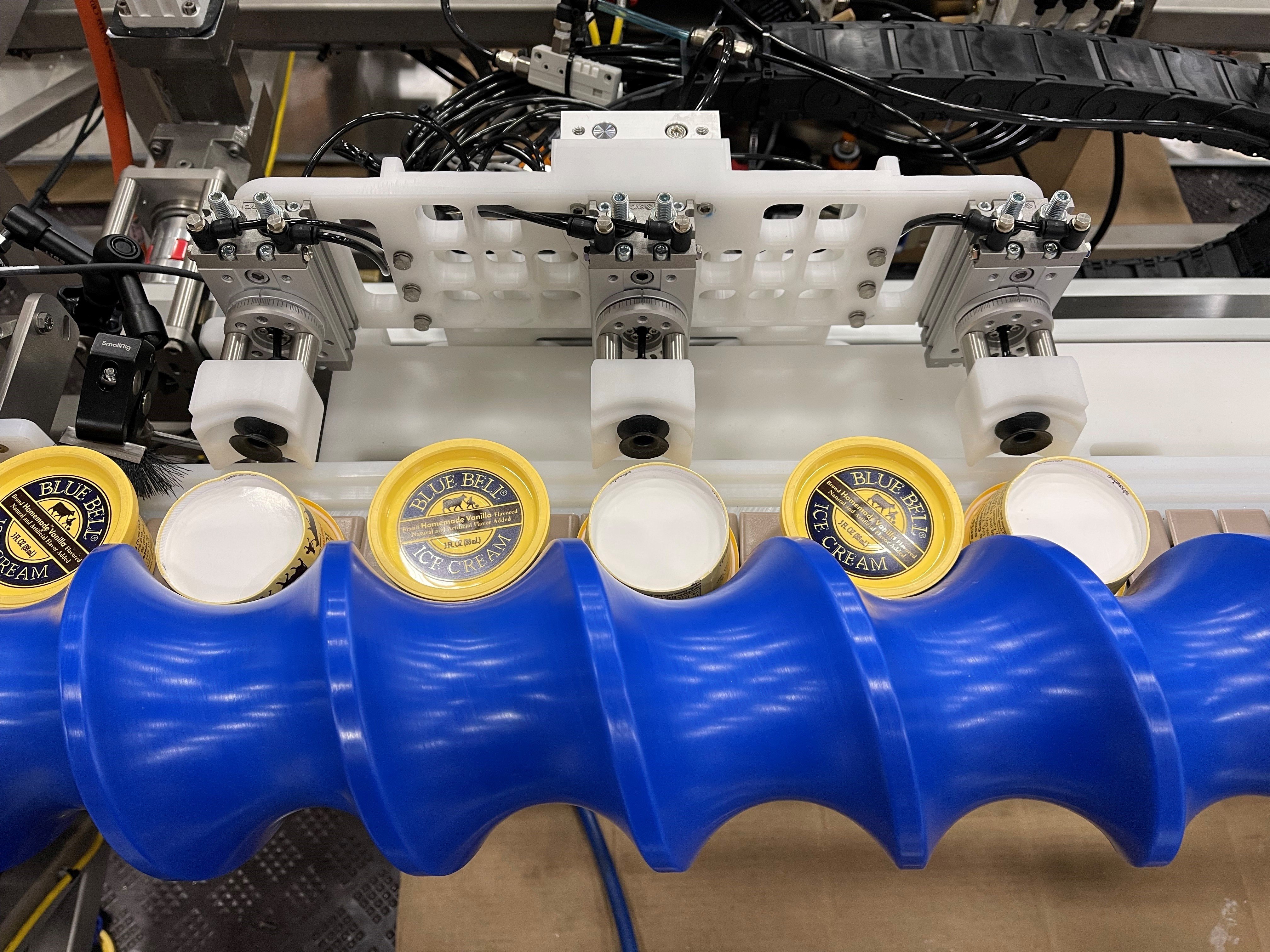

Metering Timing Screw Drive Units

Positive container handling can have a major impact on your production and control of the container. Learn how to adapt this into your line.

How to Increase Throughput

Your production is often limited by manual repetition of applications such as lane combining and dividing, orienting products, or grouping and stacking. Morrison offers products that automate these processes.

Ways to Reduce Human Error

Install down bottle rejects that mechanically reject down bottles ahead of upstream equipment to minimize jams or wasted product.

Create Positive Container Handling

As experts, we maintain positive control of your container, but we also produce change parts, timing screws, and full systems that account for fractions of differences for the tightest fits.

Meet Your New Workforce

Automating the most laborious parts of your lane is a great way to reduce workforce needs and see quick ROI on your capital investment.

Best Practices for Faster Changeovers

As changeover experts, we've compiled a few tips to implement in your plant to improve your changeover times. Follow them and see their effects.

Learn the Timing Screw Fundamentals

Download more than 50 years of expertise on timing screws and learn about the various applications they are suited for.

Meet Your Sales Representative

Dustin Lee

Vice President of Sales

C: 708-774-1490

O: 708-756-6660

dustin.lee@morrison-chs.com

Europe, Asia, Australia, and Canada

Mike Sparger

Regional Sales Manager

C: 708-793-0051

mike.sparger@morrison-chs.com

States: IL, WI, MN, IA, SD, ND.

Paul Thames

Regional Sales Manager

C: 708-728-5414

paul.thames@morrison-chs.com

States: AL, SC, NC, TN, GA, VA, FL

Karson Wehrli

Inside Sales

C: 513-235-3696

karson.wehrli@morrison-chs.com

States: MI, OH, KY, Lawrenceburg, IN and Southern IN

Nicholas J. LaRocca

Regional Sales Manager

C: 201-774-9840

nick.larocca@morrison-chs.com

States: NH, NJ, NY, MA, RI, CT, PA, VT, ME, DE, MD

Enrique Tapia

Regional Sales Manager

C: 708-728-5913

enrique.tapia@morrison-chs.com

States: CA, AZ, NV

Brett Gill

Regional Sales Manager

C: 708-701-3946

brett.gill@morrison-chs.com

States: CO, NE, KS, MO, OK, AR, TX, LA

Jay Del Rio

Latin American Key Account Manager

P: 708-983-6676

jay.delrio@morrison-chs.com

Northern IN, NM, UT, MS, WV, Mexico, Latin America

Seth Licke

Aftermarket Customer Service Manager - Service Sales

P: 708-774-1492

seth.licke@morrison-chs.com

.png?width=1920&height=600&name=Copy%20of%20Logistic%20Email%20Header%20%20(1920%20%C3%97%20600%20px).png)