Introducing the Model 20 Can Opener: Revolutionizing Bulk Can Processing

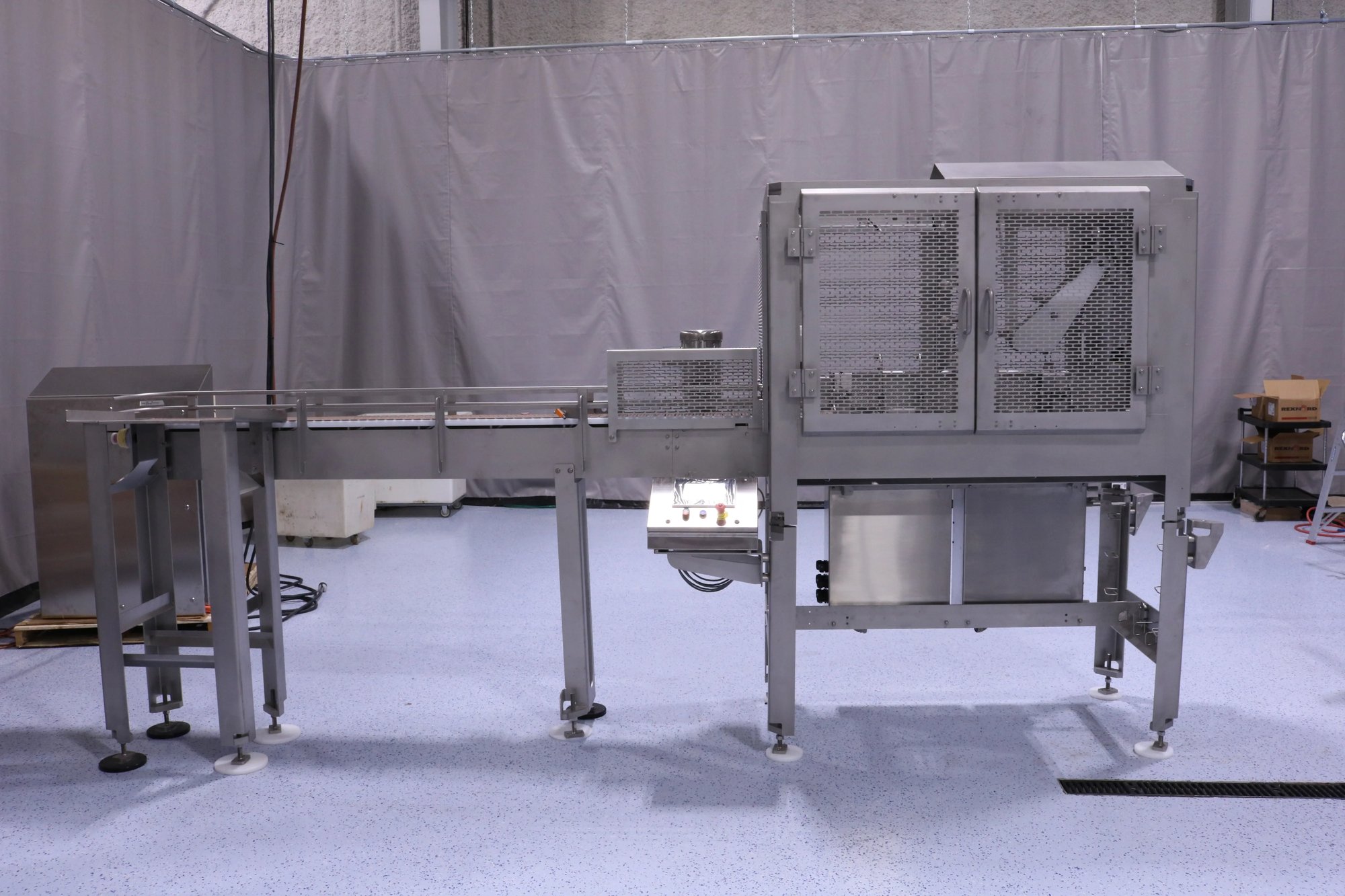

The Model 20 Automated Industrial Can Opener is a cutting-edge solution tailored for food processors and manufacturers who need an efficient, safe, and reliable method to handle #10 cans for bulk food preparation. Designed to streamline your operations, the Model 20 integrates advanced automation into your production line, significantly reducing manual labor, enhancing safety, and meeting the challenges of today’s workforce shortages.

Why Choose the Model 20?

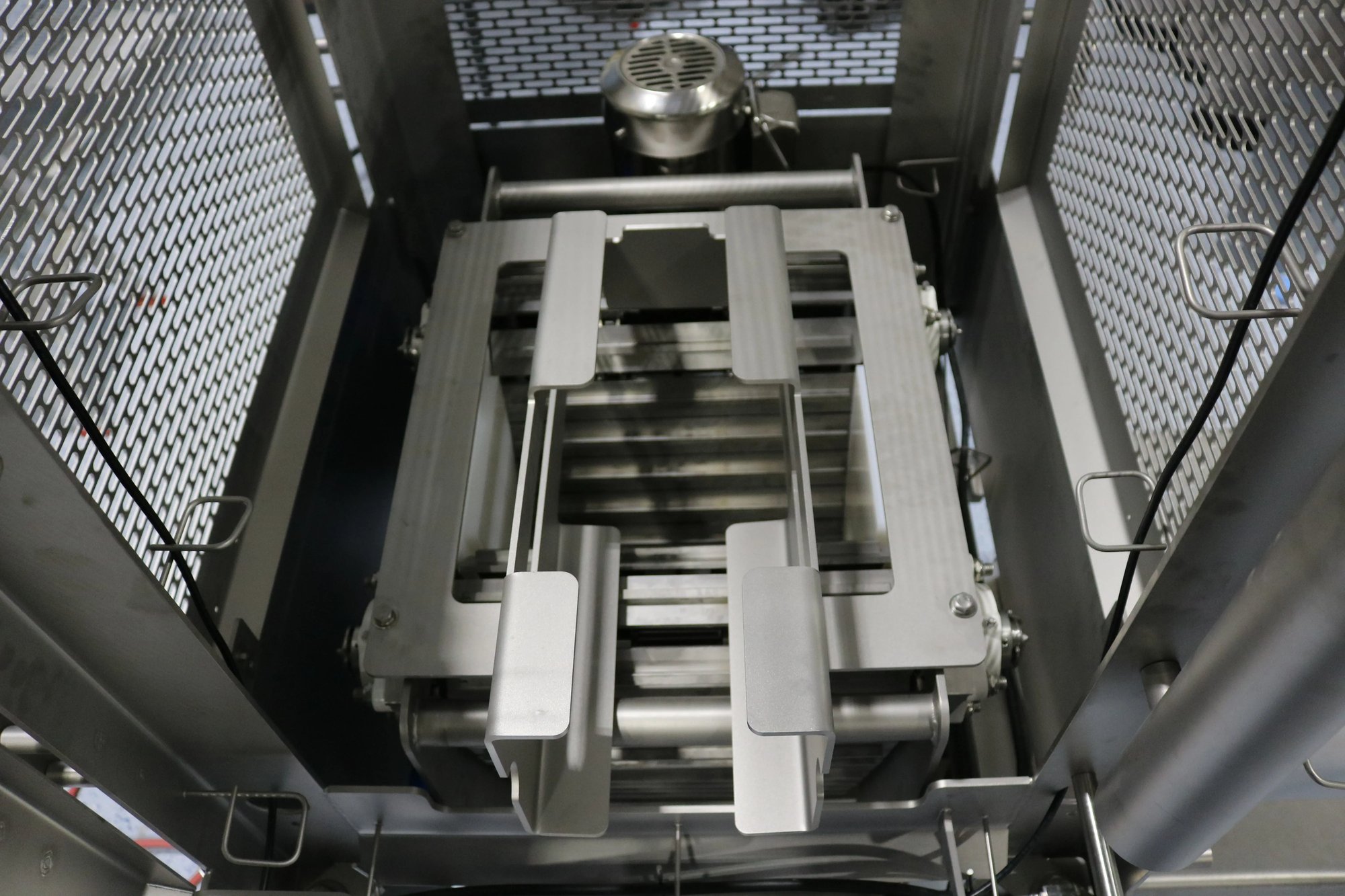

Manual can opening is time-consuming, inconsistent, and presents safety risks to employees. The Model 20 addresses these issues by automating the process of rinsing, opening, dumping, and crushing bulk cans, all while maintaining operator safety through robust perimeter guarding. The system shuts down automatically if doors are opened, ensuring a safe working environment.

With high washdown compliance and built-in versatility to accommodate different can sizes and viscosities, the Model 20 is engineered to deliver efficiency without compromise. Whether you’re running viscous products or varying can sizes, the Model 20 can be tailored to meet your production requirements.

A Scalable and Cost-Effective Solution

The Model 20 is designed with versatility in mind, offering optional add-ons such as can crushing and dumping to further enhance its functionality. These features enable the system to not only open and clean cans but also empty their contents and crush them for recycling and efficiently. By incorporating these capabilities, the Model 20 helps plants achieve sustainability goals, reduce waste, and streamline their production processes. This makes the Model 20 an investment that not only boosts efficiency but also delivers long-term profitability and environmental benefits.

Learn More

For inquiries about the product, fill out the form below, and one of our experts will contact you shortly.

Key Benefits of the Model 20

All-in-One System

Simplify your can processing workflow with a fully automated solution capable of rinsing, opening, dumping, and crushing cans in one seamless operation.

Enhanced Safety Features

Safety guarding and automatic shutdowns protect workers during operation.

Reduced Labor Dependency

Automate previously manual tasks, freeing up your workforce for higher-value activities and minimizing labor constraints.

Scalable for Your Needs

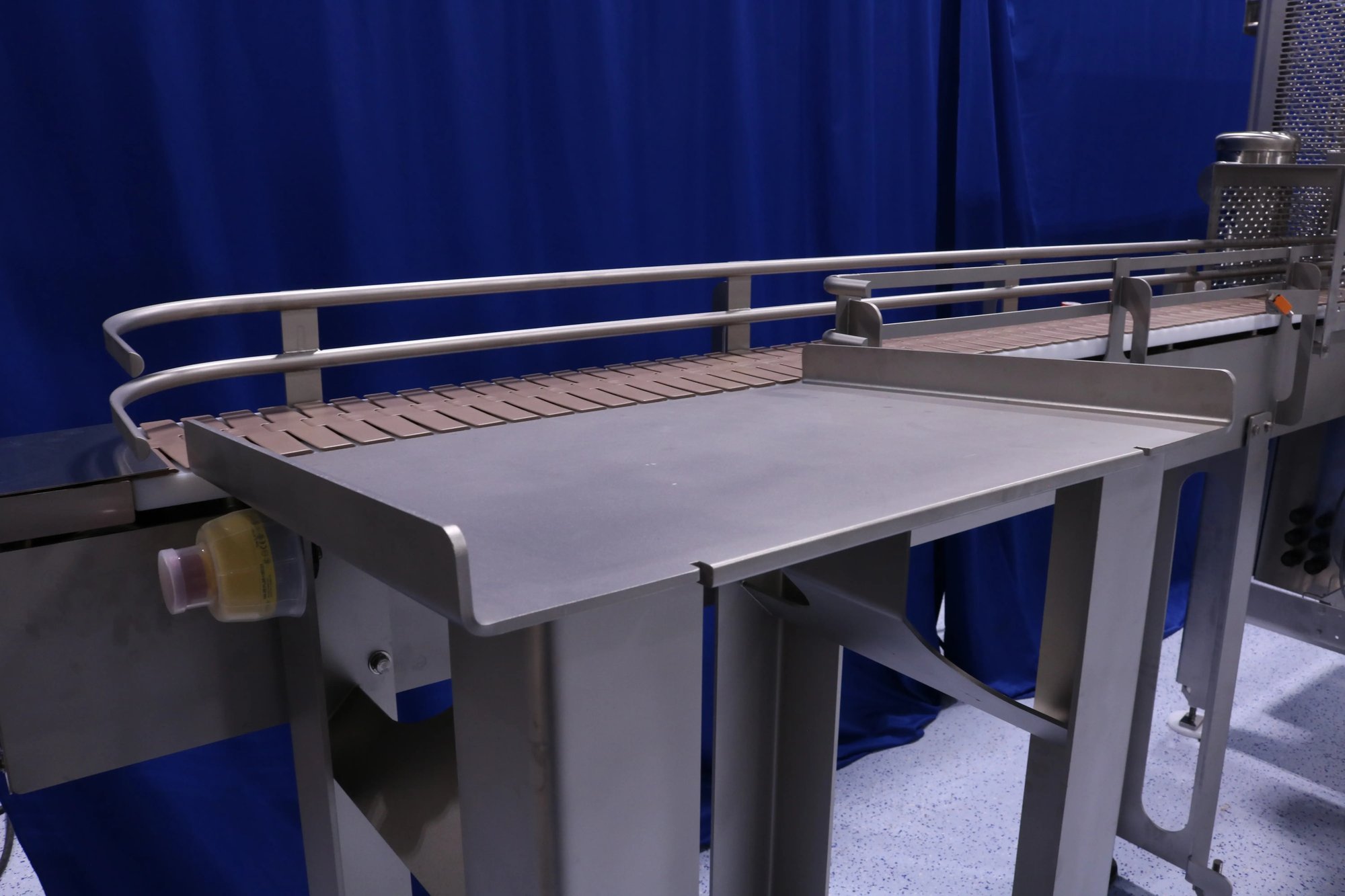

With modular options, the Model 20 can be adapted to fit your conveyor layout, product viscosity, and production speed requirements.

Check Out Our Can Opener eBook

Ready to Upgrade Your Packaging Line?

Your Model 20 purchase comes with everything needed to start processing cans efficiently: a loading table, pre-rinse and air blow-off station, crown punch, magnetic de-lidder, metal twist screw, can cleaning station, and safety guarding. Optional add-ons such as infeed conveyors, can crushers, and punch-and-blow systems are available to further enhance your setup.

Upgrade your can processing capabilities with the Model 20 Automated Industrial Can Opener—a solution that combines innovation, safety, and scalability to help your business succeed. Contact Morrison today to learn more or place your order!